Seaborg is developing a nuclear power plant concept fundamentally different from what exists today.

We will only reach our goals for decarbonisation if the alternative is cheap enough and scales fast.

Our vision is to transform energy markets and out-compete fossil fuels to create a bright future with abundant clean energy for everyone.

We will do this by executing a rapid world-wide deployment of the Compact Molten Salt Reactor via shipyard serial production of Power Barges.

The Seaborg Compact Molten Salt Reactor (CMSR) is an advanced, small, and modular molten salt reactor characterized by the use of liquid

fluoride molten salt fuel and a patented liquid molten hydroxide moderator.

The CMSR produces approximately 100 MWe through the fission of High-Assay Low-Enriched Uranium (HALEU) in a thermal neutron spectrum.

The liquid moderator, which does not accumulate irradiation damage, enables an operating life of 12 years per CMSR, during which no refueling

is required. The fuel and moderator salts have high boiling points, and the CMSR therefore does not require pressurization above what is

needed to circulate the salts.

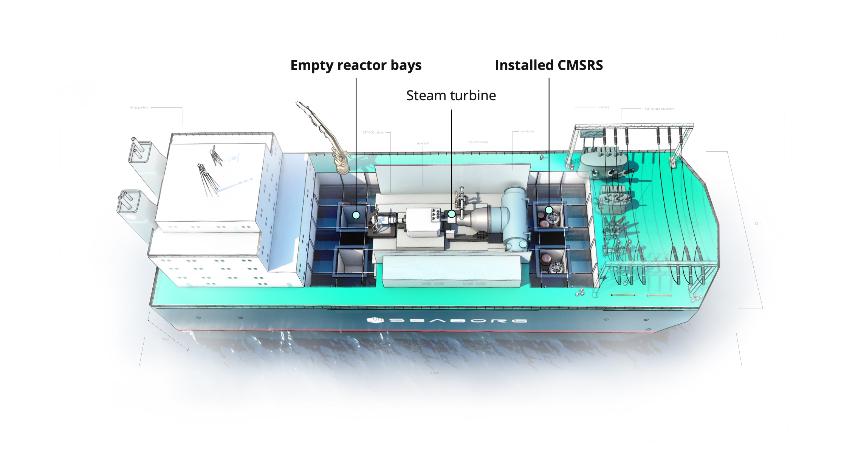

The CMSR Power Barge consists of one or more power modules connected to an aft end module and a fore end module. The design includes a complete double hull providing protection to all systems.

| Length | Net electrical output |

CO2 savings (24 years operation) |

|

|---|---|---|---|

| 2x CMSR | 115 m | 200 MWe | 33.6 - 43.6 megaton |

| 4x CMSR | 185 m | 400 MWe | 67.2 -87.2 megaton |

| 6x CMSR | 255 m | 600 MWe | 100.8 – 130.8 megaton |

| 8x CMSR | 325 m | 800 MWe | 134.2 – 174.2 megaton |

Each power module has two reactors installed and two empty reactor bays. Each reactor has its own independent salt systems and steam generator.

The empty reactor bays are for a new reactor to be installed when the first reactor reaches the end of its 12-year fuel cycle. The two operating

steam generators feed one turbine train.

The CMSR design philosophy is focused on implementing inherent and passive safety features as well as fully automated shutdown. The design ensures high proliferation resistance, reduced complexity, modularity, and increased manufacturability.

Seaborg applies a systems engineering approach for systematic and consistent development of the CMSR Power Barge design. The CMSR comprises the following systems:

The fissile component of the fuel is HALEU. The enrichment level enables an operating lifetime of 12 years without refueling. The fuel consists of NaF, KF, and UF4, with partial reduction of UF4 to UF3 to limit degradation of the structural materials. Partial reduction is maintained throughout the operating lifetime by the chemistry control system.

Chemistry control is implemented for each molten salt circuit. Seaborg implements a proprietary technology in the chemistry control system of

the moderator circuit which limits the corrosion and enables CMSR lifetime.

The fuel salt chemical control maintains partial reduction of UF4 to UF3 and continuously removes fission products from the primary circuit to

maintain the redox potential that is necessary to minimize uniform corrosion during normal operation and transients.

The secondary salt chemistry control system ensures that the secondary coolant properties remain within operational design limits.

| Major technical parameters | |

|---|---|

| Reactor type | Molten salt reactor / thermal spectrum |

| Coolant / moderator | Fluoride fuel salt / sodium hydroxide salt |

| Thermal / electrical capacity | 250 MWt / 100 MWe per reactor |

| Primary circulation | Forced circulation |

| Operating pressure (primary / secondary / nuclear steam supply system) | 0.45 / 1.05 / 18 MPa |

| Core inlet / outlet coolant temperature | 600 / 670 ºC |

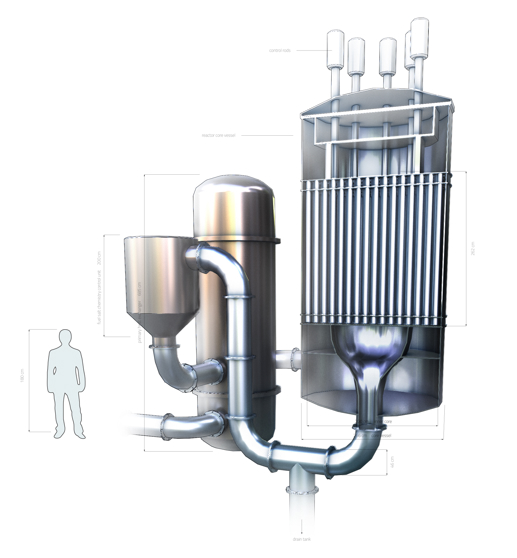

| Reactor pressure vessel height / diameter | 5.5 / 2.5 m |

| Reactor pressure vessel weight | 50 – 60 metric ton |

| Power conversion process | Superheated steam driven turbine / generator |

| Approach to safety | Automatic shutdown, passive cooling |

| Reactivity control mechanism | Negative temperature coefficient, regulating and safety rods, fuel salt draining |

| Fuel type / assembly array | HALEU / molten salt fuel |

| Fuel cycle approach | HALEU one cycle, off-site reprocessing |

| Refueling cycle | 12 years / no online refueling |

| Design life | 12 years per CMSR / 24 years per Power Barge |

The CMSR power barge is an energy solution that can fit into any market. Since it is modular (200-800 MWe) it can deliver a wide range of power

outputs. The CMSR power Barges is serially produced at shipyards that allows for a fast deployment and cost reduction.

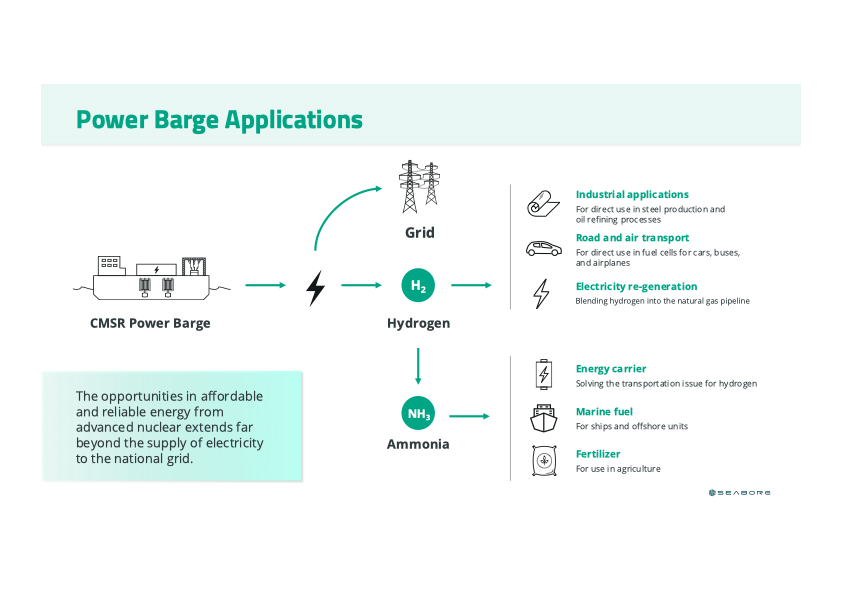

The CMSR Power Barge can reach remote locations and deliver electricity (different capacities) to integrated or distributed power grids. It can also deliver electricity to Power to X. In combination with a modular hydrogen production plant, it can deliver hydrogen that in turn it can be converted into other alternative fuels such as ammonia. Seaborg aims to create a sustainable future by enabling large scale production of clean energy for everyone.